Brush type self-cleaning filter

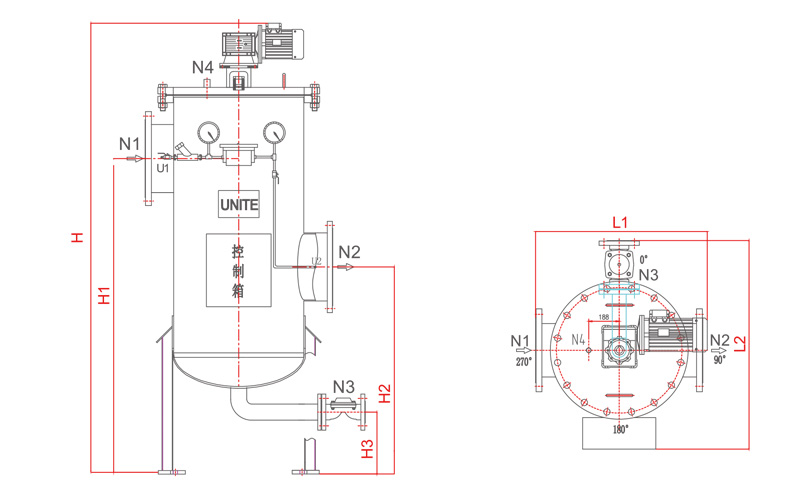

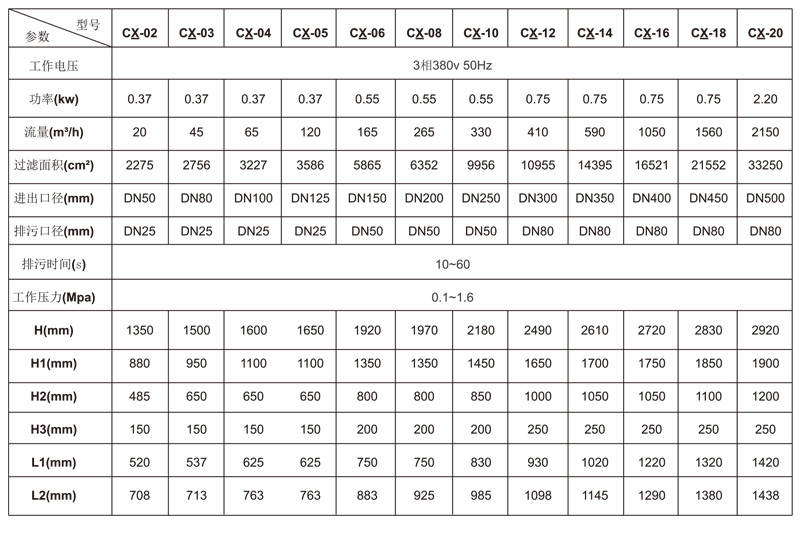

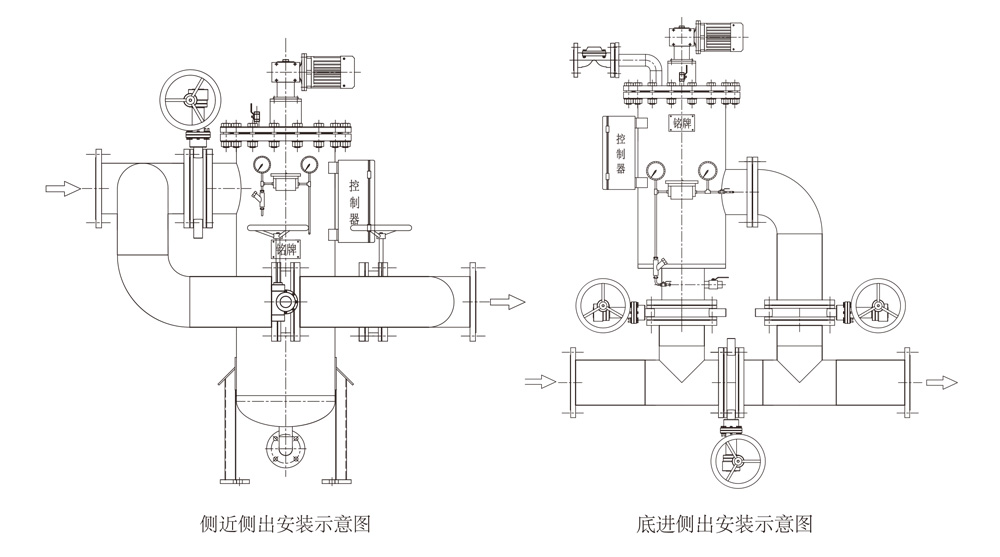

U - ZC - S brush type self-cleaning filter series is suitable for harsh conditions. 25 ~ 3500 micron strainer with 2 "- 36" diameter can be equipped based on the operation requirements. The cleaning process is initiated by the all time monitored differential pressure between the entrance and exit. This pressure differential is usually preset as 0.5 bar (7 psi). The filter has the advantages of continuous filtration, convenient maintenance, safe operation, etc. and is thus widely used in many industires.

Working principle:

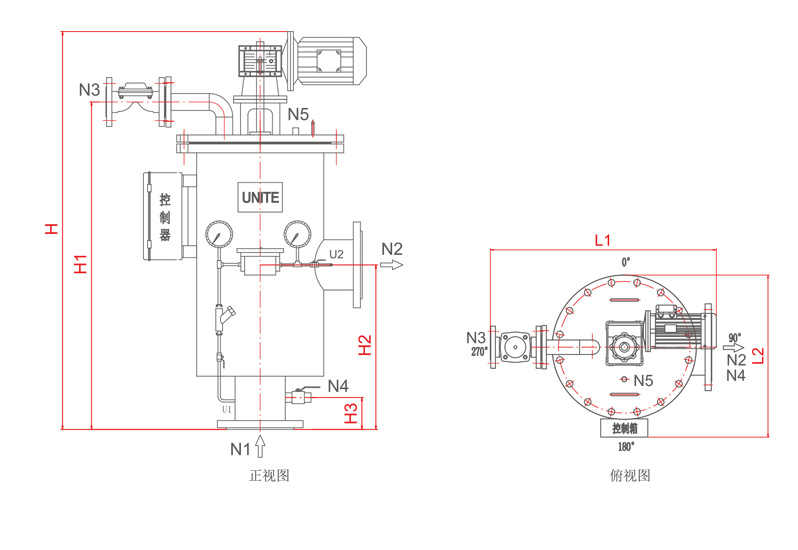

When filters import and export of differential pressure reaches the preset value (0.5 bar) or time value, the filter will start from the cleaning process, the whole process of self-cleaning contains two steps: open on the filter diaphragm drain valve on the end cover;Stainless steel brush rotation, within the motor drives the strainer screen by screen capture of the impurity was under the steel brush and is discharged from the drain valve.The whole cleaning process takes about 15 to 30 seconds, when cleaning, the system does not block the whole operation process of the filter provided by a control box to control.

Cleaning steps:

1. When the pressure differential switch detected that the pressure difference between the inside and outside of the filter mesh reaches the preset value (0.5 bar).

2. The drain valve is opened to the air.

3. The motor drives the steel brush in the mesh to rotate.

4. The membrane drain valve is closed.

Application fields:

Filtration mode: filtration, separation, screening, mechanical, manual, brush, scraper, intelligent automatic, continuous online cleaning.

Filtering purpose: filter large particle impurities, clean required liquid, collect required solid particles, protect key equipment ○ application industry: water treatment, pharmaceutical technology, food and beverage, petrochemical industry, power, electronics, printing and dyeing, construction, smelting, papermaking, coal mine, municipal administration, etc.

Suitable for liquids: water, penicillin, protein, polymer, vitamin, citric acid, fermented liquid, chitosan, agarose (gel), silicone solution, wax, kerosene, monomer, soap, sorbitol, steroid, wet auxiliary, adhesive, pigment, ink, slip agent, paint, resin, rubber, ethanol, chocolate, milk, edible oil, high temperature oil, fruit juice. , coolant, diesel, etc.

Brand-name products in Jiangsu," "National Customer Satisfaction Brand" and the honorary title of the winner.

- E-mail:unite@unitefilter.com

- Address:No. 24 all the way,industrial park,new area,Wuxi