Sucking type back flush filter

U - ZC - X1 X2 series sucking and scanning self-cleaning filters has two types of structures: vertical and horizontal. With a decelerate gear motor driving cleaning mechanism and a unique multi-layer stainless steel mesh, the filtration precision can reach up to 10 microns; The sucking and scanning technique consumes less than 1% of the total water - the lowest emission water consumption among all the self-cleaning modes (the rate is adjusted according to the specific application situations ).

Product Features:

Compact body, firm and reliable structure

Small backwash water consumption, low water pressure demand

High filtration precision, suitable for all kinds of water quality

Small backwash pressure reduction, no affect on normal water supply

working principle:

Filtration process: water enters from the filter inlet and passes through the coarse filter screen from the outside to the inside, and then flows out from the inside of the fine filter screen. Impurities in this process are intercepted by the fine filter screen and form a certain head loss. The coarse filter screen is designed to protect the cleaning mechanism from damage by large particles of impurities, which does not play a filtering role.

Self cleaning process: when the pressure difference inside and outside the filter screen reaches the preset value or the timing cleaning switch reaches the set time, the system starts the self-cleaning process.

The whole cleaning process is completed by a sucking scanner, which carries out a spiral scanning movement to suck down the impurities on the inner surface of the filter screen and discharge them through a blowdown valve. The scanner is driven by a two-way rotating electric motor through a screw rod.

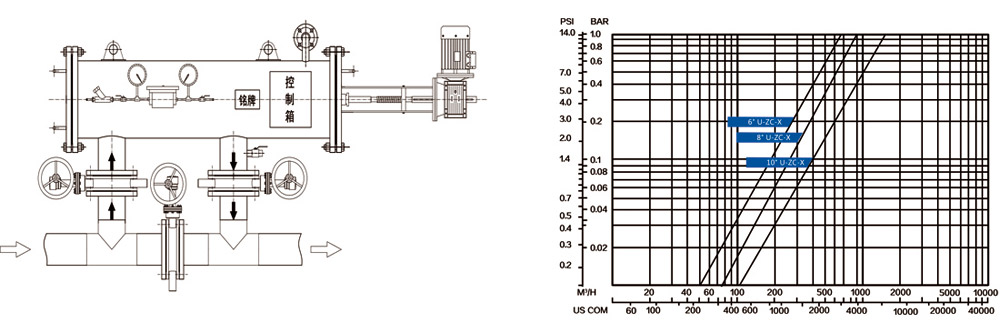

The opening of the blowdown valve is controlled by a two position three-way solenoid valve. The whole blowdown process lasts for about 35 seconds, and the system is not cut off in this process.Installation diagram and pressure loss table:

Brand-name products in Jiangsu," "National Customer Satisfaction Brand" and the honorary title of the winner.

- E-mail:unite@unitefilter.com

- Address:No. 24 all the way,industrial park,new area,Wuxi